Over the next several months, Maersk Lines will be giving ten container ships in its fleet nose jobs. They will be cutting off the existing bulbous bows and retrofitting them with new more energy-efficient designs.

Over the next several months, Maersk Lines will be giving ten container ships in its fleet nose jobs. They will be cutting off the existing bulbous bows and retrofitting them with new more energy-efficient designs.

It all has to do with slow steaming. Bulbous bows are designed to work at a particular range of speeds and drafts. A well designed bulbous bow can reduce fuel consumption by 10-12%. Many of the Maersk ships were originally designed to operate at around 24 knots. With the dramatic rise in fuel costs and continued container ship overcapacity, many ships are now operating at speeds as low as 12 knots. At such slow speeds the original bulbous bow designs can actually increase hull resistance and increase fuel costs. The new bulbs should save 1-2% in fuel costs.

The nose job: Why 10 of our ships are getting a new bulbous bow

Why is Maersk going to the trouble and expense? The modifications to the hulls of ten ships suggests that Maersk is convinced that slow steaming is here to stay. To understand why and what they are doing, a few brief comments on what makes a bulbous bow work are in order.

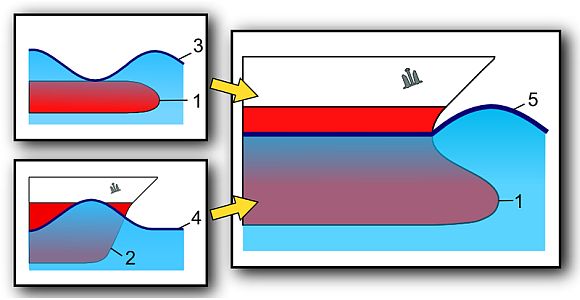

Every ship traveling through the water creates a bow wave. Creating this wave takes a lot of energy. A sphere moving just underwater creates its own wave, followed by a trough. If you position the sphere just in front of the bow of the ship in the form of a “bulb,” it is possible to align the trough created by the moving sphere with the crest of the bow wave, effectively cancelling each other out.

The problem is that the position of the waves created by the bulb and the hull only align under a certain range of speeds and drafts. Slow down or speed up too much and the waves no longer cancel out. In the worst case, the waves become additive and can increase resistance and fuel costs, which is apparently the problem that Maersk has been facing whe it slowed down ships originally designed to travel at much higher speed..

This is applied Fluid Dynamics at its best.

The Sea Land SL-7’s traveled at twice the speed of all container ships from that era. Alas the First Arab oil embargo, meant shutting down one boiler, and steaming at half speeds. Uncle Sam took them over, renamed them and they became Algol class T-AKR crane ships. The Government has the Titanium Exxon card!

I found it interesting that u mentioned the S/L 7. I worked in Oakland when the new vessels came on line. They were later replaced with diesel ships due to the high cost of fuel. RJR sold them to the gov and they made them into pre-positioned ships loaded with the articles of war.

If memory serves me they were over a thousand feet long or just under.

I do know they increase our work load in the reefer dept due to the increased reefer load they could carry.

Norvin Seal Land 1967-1973