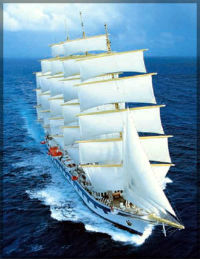

Here is a look at a modern sailing ship, Star Clipper’s Royal Clipper, a high-tech square-rigger whose technology is not always obvious. Click here for a photo tour of the Royal Clipper recently featured in USA Today.

Here is a look at a modern sailing ship, Star Clipper’s Royal Clipper, a high-tech square-rigger whose technology is not always obvious. Click here for a photo tour of the Royal Clipper recently featured in USA Today.

We recently posted about the high-tech three-masted square-rigger, Black Pearl, which features a next-generation Dynarig with automated sail trimming and furling. Flexible solar panels are also incorporated into the sails to help meet the electrical needs of the vessel.

Compared to the Black Pearl, the five-masted fully-rigged sailing cruise ship Royal Clipper looks almost entirely traditional. This is no accident. The Royal Clipper is modeled after the famous Flying P Liner, the five-masted ship Preußen of 1902.

According to the Guinness World Records, the 439′ Royal Clipper is the largest square-rigged ship in service, with 5,202 square meters of sail area (or almost twice that of the Black Pearl.)

The Royal Clipper sets 42 sails, set on yards and stays in what at first glance looks like a wholly traditional rig. In fact, it is anything but. The 26 square sails can all be set or furled from deck at the push of a series of buttons. The square sails are furled inside the hollow aluminum yards with a hydraulic roller furling system. The yards are trimmed with electric brace winches.

Furling square sails is not a new idea. Variations on the concept date back at least to at least 1861, with H.D. Cunningham’s Patent Self-Reefing Topsails. The advent of hydraulics, electric motors, lightweight spars and stainless steel cable, however, make it possible to fully automate the handling of the square sails carried on the five masts.

The staysails on the Royal Clipper are raised with electric deck winches, which allow the passengers to line up on deck and help tail the sheets as the staysails are raised, allowing each participant to go home from the cruise saying that they helped raise the sails on the world’s largest square-rigger.

Whereas the Preußen had a sailing crew of around 45, the Royal Clipper deck crew is about 20. (As the Royal Clipper is a cruise ship, the total crew is over 100 to meet the needs of 227 passengers.) Under sail, the Royal Clipper is capable of speeds of over 14 knots.

Other technology is not obvious either. Because passengers make for fussy cargo, the heel of the ship is limited by automatic heeling tanks which also serve as anti-rolling takes when the ship is at anchor.

The upper sections of the two tallest masts at 60 meters also can fold down to allow the ship to pass under the Queen Elizabeth II bridge on the Thames. The main engine and generator exhausts are vented through the mizzen and jigger masts, well away from passengers or other rigging.

Star Clipper will be adding a new and larger square-rigged cruise ship to its fleet within the next few months. The Flying Clipper will be a 300 passenger ship inspired by the France II of 1911.

As a square-rigger, with winds from astern or on the quarter, wouldn’t it

make more sense for engine exhaust to vent from the Foremast. Or are passengers restricted from the aft end of the ship so that works better?

Do the masts need stays or shrouds, or have them for a more realistic appearance?

I think the primary reason that the mizzen and jigger masts were used is because they are roughly over the engine room. If the wind is light and the vessel is motoring, the apparent wind will be forward of the beam and carry the smoke away aft. I think the main goal in using the mast as uptakes is to try to get the exhaust as high above the deck and away from the rigging and sails as possible.

Considering that the old world of sail was killed as much by (1) intensive labor and all the complications that come with people as it was by (2) modest speed and (3) slightly uncertain arrival times, it’s exciting to see us circle back and have another go with updated machinery. Take away any of those three problems and suddenly some proportion of cargo is sail-compatible.

Plus of course having a decent auxiliary engine means no more waiting for days to claw out of some bight, firth or estuary.

Is the the Peking, recently returned to Hamburg, related Preusen?

The fate of the Preussen: Built at Techlenborg’s Yard in Germany in 1901, 482ft. long, she was capable of 20 knots.

Near Midnight on 5th.November, 1910, en route for Chile, she was sailing South-West down the English Channel at some 16 knots when she was hit by the Denny built 273ft. turbine steamer Brighton, which completely misjudged her speed in the dark, carrying away her bowsprit, part of her foremast and much of her steel cable rigging. The Brighton returned to Newhaven to summon assistance. The tug Alert towed Preussen 60 miles to anchor off Dover Harbour. In a rising gale both anchor chains parted and she was driven ashore near Crab Bay, South Foreland where sadly she broke up. Her hull can still be seen at low water Springs.

In 2014 the cruise ship Saga Sapphire had to anchor off South Foreland. On weighing the anchor it was found to have snagged a long 2 inch steel cable. Could it have been one of Preussen’s forestays?